Containing the Cloud: Your Comprehensive Guide to a Negative Pressure Smoking Room

By the Team at Commercial Air Purifiers Published: October 7th, 2025

You’ve designated a smoking area, but the faint, unmistakable scent of cigarette smoke still manages to wander down hallways, seep under doorways, and generate complaints from employees, tenants, or guests. It’s a frustratingly common problem for facility managers, business owners, and property managers everywhere. The intention was to contain the smoke, but reality often falls short, leading to poor indoor air quality and unhappy non-smokers.

The issue isn't just the odor; it's the complex mixture of harmful chemicals and particulate matter that escapes and contaminates surrounding areas. If you're struggling to effectively isolate a smoking environment, you're in the right place. This guide will walk you through the science and practical application of creating a negative pressure smoking room—the gold standard for smoke containment—and explain why pairing this strategy with the right air purification is the key to a truly comprehensive solution.

The Lingering Problem: When Designated Smoking Areas Fail

The health risks associated with secondhand smoke are not up for debate. According to the Centers for Disease Control and Prevention (CDC), secondhand smoke contains more than 7,000 chemicals, of which hundreds are toxic and about 70 can cause cancer. There is no risk-free level of exposure. When a smoking lounge or room is improperly sealed or ventilated, it actively exposes non-smokers in the building to these dangers, undermining the very purpose of its creation.

Beyond the immediate issue of secondhand smoke, there's the insidious problem of thirdhand smoke. This refers to the residue from tobacco smoke that clings to surfaces like walls, carpets, furniture, and ventilation ducts long after a cigarette has been extinguished. These toxic particles can re-enter the air and be inhaled, posing a continued health risk. A 2020 study published in the journal Toxicology Reports highlights that this residue can react with other indoor pollutants to form new, harmful compounds over time.

Simply putting up a sign on a door doesn’t create a barrier against these microscopic threats. Air is a fluid; it moves through the smallest cracks and follows the path of least resistance. Without a system designed to control airflow, you are essentially hoping the smoke decides to stay put. This is where the principles of physics and engineering offer a reliable and effective answer.

The Core Concept: What Is a Negative Pressure Room?

At its core, a negative pressure room is an isolation technique used to contain airborne contaminants, whether in a hospital protecting against infectious diseases or in a commercial building controlling tobacco smoke.

The principle is surprisingly simple: more air is mechanically exhausted from the room than is supplied to it.

Imagine a box with a fan pushing air out and only a small opening for air to come in. The fan creates a lower pressure environment inside the box compared to the surrounding area. Because air naturally flows from an area of higher pressure to an area of lower pressure, air from outside the box will be continuously pulled into the box through the opening.

In the context of a smoking room, this means that when the door is opened, air from the hallway rushes in, preventing the smoke-filled air inside from escaping out. This containment is the single most critical function of a negative pressure system. It directs the flow of air, ensuring that all contaminants generated within the room are captured and exhausted directly outside, rather than being allowed to migrate throughout the building.

The Three Pillars of an Effective Negative Pressure System

Creating this pressure differential isn't as simple as installing an exhaust fan and calling it a day. It requires a balanced system built on three essential components:

-

A Dedicated and Powerful Exhaust System: This is the engine of the operation. The exhaust fan must be powerful enough to remove a specific volume of air from the room, measured in Cubic Feet per Minute (CFM). The required CFM depends on the size of the room and the desired number of air changes per hour (ACH). Industry standards, such as those from ASHRAE (American Society of Heating, Refrigerating and Air-Conditioning Engineers), often recommend high ACH rates for smoking lounges to ensure contaminants are diluted and removed quickly. The exhaust must be ducted directly to the exterior of the building, away from any air intakes or public spaces.

-

Airtight Room Construction: For negative pressure to be maintained, the room must be sealed as tightly as possible. Any leaks will compromise the system, allowing contaminated air to escape and clean air to enter from unintended places. This involves sealing all penetrations in the walls, ceiling, and floor, including around light fixtures, electrical outlets, and plumbing. The door is a primary point of leakage and should be fitted with high-quality gaskets and a door sweep to create a firm seal when closed.

-

A Controlled Source of Make-Up Air: Since you're constantly exhausting air from the room, you need to replace it. This is known as "make-up air." Without a planned source for this air, the powerful exhaust fan will pull it from wherever it can—through cracks in walls, from the ceiling plenum, or from other undesirable places. This can "starve" the room of air, putting a strain on the fan and potentially causing backdrafts in other building systems. The best practice is to provide a transfer grille or an undercut in the door, allowing clean, conditioned air from the adjacent hallway or space to serve as the make-up air, reinforcing the desired inward flow.

Why Ventilation Alone Is Not a Complete Solution

While a properly designed negative pressure system is masterful at containing and exhausting airborne contaminants, it's essential to understand its limitations. The primary goal of ventilation is dilution and removal. It works by constantly replacing contaminated indoor air with fresh outdoor air. However, it doesn't instantly eliminate 100% of the smoke particles and gases generated within the room.

Tobacco smoke is a complex aerosol composed of solid particles (like tar and soot) and a vast array of gases (like carbon monoxide and formaldehyde). While the exhaust fan is removing this mixture, people inside the room are still exposed to high concentrations. Furthermore, the stickier particles and vapors can settle onto surfaces before they have a chance to be exhausted, contributing to the buildup of thirdhand smoke.

This is where in-room air purification becomes a crucial second layer of defense. By capturing contaminants at the source, a high-performance air purifier reduces the overall load on the ventilation system, lowers the concentration of pollutants in the air for occupants, and helps mitigate the accumulation of thirdhand smoke residue on surfaces. The U.S. Environmental Protection Agency (EPA) notes that filtration can be an effective supplement to source control and ventilation for improving indoor air quality.

The Integrated Solution: Combining Negative Pressure with High-Efficiency Air Purification

The most effective strategy for managing a smoking environment is an integrated one: use negative pressure to contain the smoke and high-efficiency air purification to continuously clean the air within the room. This dual approach addresses the problem from all angles.

When selecting an air purification system for a smoking environment, it's vital to choose one capable of handling the unique challenges of tobacco smoke. This means targeting both the particulate matter and the gaseous pollutants.

-

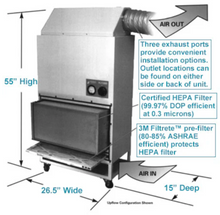

For Particulate Matter (The "Smoke"): The fine and ultrafine particles in smoke require a high-efficiency filter. Systems equipped with HEPA (High-Efficiency Particulate Air) filtration are the standard. A true HEPA filter is certified to capture at least 99.97% of airborne particles down to 0.3 microns in size, effectively trapping the soot, tar, and other solid components of smoke.

-

For Gases and Odors (The "Smell"): HEPA filters are not designed to remove gases, chemicals, or Volatile Organic Compounds (VOCs). This is the job of an adsorbent media. Systems with a substantial amount of activated carbon are critical for smoking applications. Activated carbon has a porous structure that adsorbs gas and odor molecules, trapping them and removing them from the air. For the heavy chemical load of a smoking room, a system with a deep-bed carbon filter will be far more effective and last longer than a thin, carbon-dusted sheet.

To learn more about how these technologies work together, our detailed guide on Understanding HEPA and Activated Carbon Filters offers a deeper dive.

For facilities managers looking to implement this powerful dual approach, exploring purpose-built smoking room air purifiers can provide an all-in-one, engineered solution designed for the specific demands of heavy smoke and odor removal.

A Healthier Building Starts with Smarter Air Control

Creating a space that successfully contains tobacco smoke is not just about courtesy; it's about health, safety, and compliance. A simple "Designated Smoking Area" sign is not enough to protect the occupants of your building. By embracing the proven principles of negative pressure ventilation, you establish a reliable method of containment. By supplementing that system with high-performance, in-room air purification, you actively reduce contaminant levels at the source, creating a cleaner environment within the room and providing the ultimate defense against migration.

This integrated approach ensures that you are not just masking an odor problem but are fundamentally controlling the airflow and removing the harmful pollutants that put everyone's health at risk.

Have questions about designing a smoking room for your facility? Contact our air quality specialists today for a no-obligation consultation to ensure your space is safe, compliant, and odor-free.

Frequently Asked Questions (FAQ)

Q1: What is the difference between positive and negative air pressure? Negative air pressure is created when more air is exhausted from a room than is supplied, causing air to flow into the room from surrounding areas. It's used for containment. Positive air pressure is the opposite—more air is supplied than exhausted—which causes air to flow out of the room. This is used in cleanrooms or medical environments to keep contaminants out.

Q2: Can a HEPA filter alone remove the smell of cigarette smoke? No. While a HEPA filter is extremely effective at capturing the solid particles in smoke, it cannot remove the odors, gases, and VOCs that make up the smell. For odor removal, you need a system that also includes a significant amount of activated carbon or another adsorbent media.

Q3: How much ventilation is required for a smoking room? Ventilation requirements are often dictated by local building codes and industry standards like those from ASHRAE. These are typically expressed in air changes per hour (ACH). Smoking lounges require very high ACH rates, often 15 to 30 or more, to effectively dilute and remove contaminants. A qualified HVAC professional should be consulted to calculate the specific needs for your space.

Q4: Is thirdhand smoke really dangerous? Yes. Research continues to show that the chemical residue left behind by tobacco smoke can remain on surfaces for weeks or months and can interact with other chemicals in the air to form new carcinogens. It poses a risk, especially to children and non-smoking adults who come into contact with these contaminated surfaces.

Q5: Are negative pressure smoking rooms required by law? Regulations vary widely by country, state, and even city. Many jurisdictions have Clean Indoor Air Acts that ban or heavily regulate indoor smoking. Where indoor smoking is permitted in designated areas, there are often strict requirements for independent ventilation and exhaust systems designed to prevent air from recirculating into non-smoking areas. A negative pressure design is the most common and effective way to meet these requirements. Always consult your local building codes and health departments.